Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Choosing the Right EV Charger Pile OEM Factory for Scalable Energy Solutions

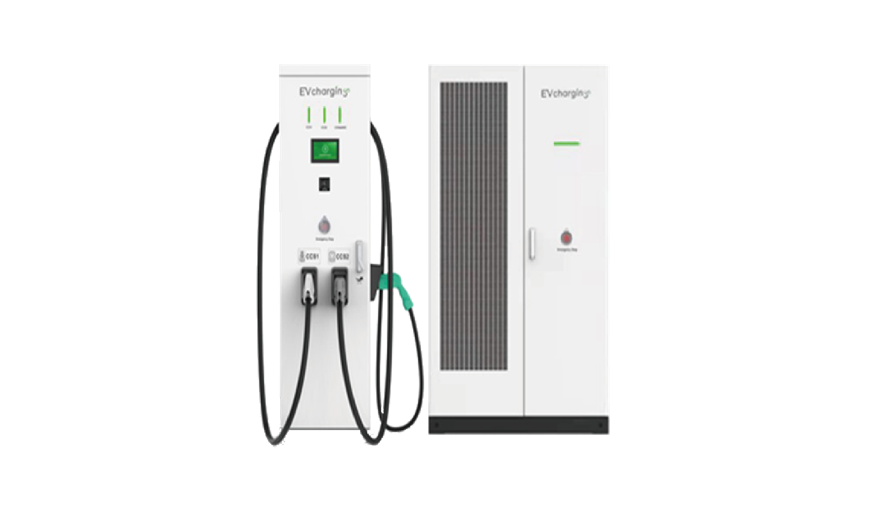

As the global shift toward clean energy accelerates, electric vehicles (EVs) are no longer a niche innovation — they're becoming the norm. With this rapid transition comes an essential need: reliable and scalable EV charging infrastructure. Central to this development is the role of the EV charger pile OEM factory, which enables brands and energy providers to offer tailored charging solutions through original equipment manufacturing.

Whether you're a startup entering the EV charging space or an established energy company expanding your charging network, choosing the right OEM partner can significantly affect your project's performance, scalability, and ROI. In this blog, we'll explore what makes an ideal EV charger pile OEM factory and how to evaluate your options effectively.

Understanding the EV Charger Pile OEM Model

OEM factories produce EV charger piles — also known as charging stations — for other companies to sell under their own brand name. These factories allow businesses to:

-

Launch EV charger products without building their own manufacturing infrastructure

-

Customize features, branding, and configurations

-

Focus on marketing, deployment, and customer experience while the factory handles production

This model is essential for accelerating market entry and scaling operations while keeping CAPEX and engineering risks manageable.

The Growing Demand for EV Charging Infrastructure

According to the International Energy Agency (IEA), the number of electric cars on the road exceeded 16 million globally in 2023, with projections suggesting exponential growth in the next decade. This creates an urgent demand for:

-

Residential EV chargers

-

Public fast-charging stations

-

Fleet and depot charging solutions

-

Smart charging systems integrated with solar and battery storage

Governments worldwide are also providing incentives for building large-scale EV charging networks, which places even more emphasis on reliable and innovative manufacturing partners.

Key Capabilities to Look for in an EV Charger Pile OEM Factory

Choosing an OEM factory isn't just about production capacity. You need a strategic partner with deep expertise in power electronics, software integration, and smart energy ecosystems. Here are the top qualities to evaluate:

1. Industry Experience in Smart Energy

A strong OEM factory should have extensive experience in smart power systems, including:

-

UPS/EPS systems

-

Communication and rail transit power

-

Battery energy storage and inverter technology

This background ensures the factory can develop charger piles that are safe, reliable, and efficient under various load conditions.

EAST, with its 35+ years in smart energy solutions, advanced R&D capabilities (800+ patents), and proven expertise in energy storage, power conversion, and microgrid systems, is well-positioned to deliver high-performance charging infrastructure tailored to industry demands.

2. Customized Solutions and Modular Design

Your OEM partner should offer modular, flexible design options to meet different use cases such as:

-

AC vs. DC chargers

-

Fast vs. slow charging

-

Integration with mobile apps and payment gateways

-

Vehicle-to-grid (V2G) or smart load balancing features

Look for factories that provide engineering support for customization — from circuit design to enclosure aesthetics.

3. Certifications and Quality Standards

A trusted EV charger pile OEM factory should comply with international standards such as:

-

CE, UL, TUV certifications

-

ISO 9001/14001 quality management systems

-

RoHS and other environmental directives

These certifications ensure that the products meet regulatory standards across different markets.

4. R&D and Innovation Capacity

The best factories invest heavily in research and development. For example, factories with hundreds of patents and proprietary technologies tend to offer more advanced features such as:

-

Intelligent power distribution

-

Real-time diagnostics and maintenance alerts

-

Seamless grid integration

Advanced R&D also allows for quicker adaptation to evolving EV and battery technologies.

5. Global Delivery and Support

OEM factories with global presence and logistics networks can help you scale beyond your local market. Check if they offer:

-

Multi-country technical certifications

-

Regional maintenance partnerships

-

Localized firmware and software customization

Support in multiple languages and time zones is a bonus when managing international deployments.

Trends Shaping the Future of EV Charging

Partnering with an experienced EV charger pile OEM factory also means staying ahead of the curve. Some key trends shaping the industry include:

Smart Grid Integration

EV charger piles are no longer standalone devices. Increasingly, they are part of larger microgrid ecosystems that include:

-

Solar photovoltaic (PV) systems

-

Battery energy storage

-

Demand response programs

-

Energy trading platforms

Factories that also work in new energy fields (like PV inverters and microgrids) offer more holistic solutions.

Edge Computing and IoT-Enabled Charging

Some OEMs now embed edge computing capabilities directly into charger piles, enabling real-time data processing, AI-based fault detection, and predictive maintenance — without relying solely on the cloud.

Modular Data Centers for EV Fleet Charging

In areas with high EV density or commercial fleets, some OEMs provide containerized modular data centers that manage power distribution, charging load optimization, and data security in one plug-and-play package.

Why the Right OEM Partner Matters

Choosing the wrong OEM factory can lead to:

-

Delays due to quality issues or failed certifications

-

Incompatibility with smart grid infrastructure

-

Limited ability to scale or customize

-

Increased after-sale service and maintenance costs

On the other hand, the right EV charger pile OEM factory becomes an extension of your team, helping you:

-

Shorten your go-to-market timeline

-

Deliver a better customer experience

-

Maintain reliability and uptime

-

Future-proof your charging infrastructure

Final Thoughts

As the electric vehicle (EV) market grows, investing in reliable charging infrastructure is essential. A strong partnership with an Original Equipment Manufacturer (OEM) is crucial for building a scalable and sustainable EV charging business.

When choosing an OEM, look for those that provide comprehensive services, including smart energy solutions and globally compliant hardware. These partners like EAST will help you remain competitive, meet regulatory standards, and support the global shift towards clean transportation.